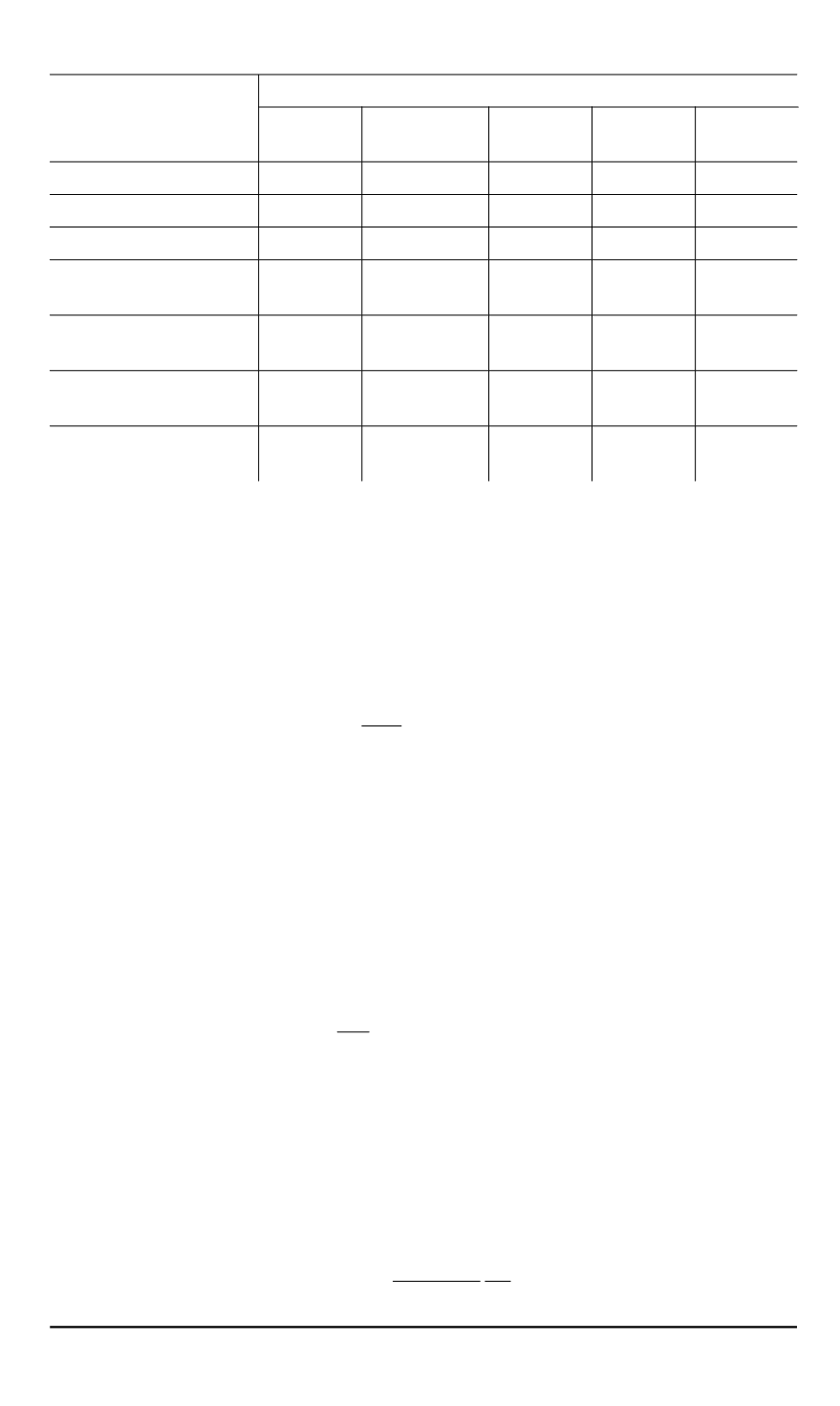

Physical parameters of materials

Material parameters

Material

Aluminum

(Д16Т)

Steel

(12Х18Н10Т)

Silicon (Si) Sapphire

(Al

2

O

3

)

Quartz

(SiO

2

)

Density,

ρ

, kg/m

3

2800

7900

2320

3980

2220

Poisson’s ratio,

ν

0.33

0.30

0.28

0.25

0.18

Young’s modulus,

E

, Па 7.08

∙

10

10

1.98

∙

10

11

1.30

∙

10

11

4.40

∙

10

11

7.20

∙

10

10

Heat expansion rate,

α

,

1/

◦

C

2.30

∙

10

−

5

1.66

∙

10

−

5

4.20

∙

10

−

6

6.60

∙

10

−

6

6.00

∙

10

−

7

Specific heat,

C

p

,

J/kg

∙

◦

C

922

462

1414

790

728

Volumetric heat capacity,

С

V

, J/m

3

∙

◦

C

2.58

∙

10

−

6

3,65

∙

10

−

6

3.28

∙

10

−

6

3.14

∙

10

−

6

1.62

∙

10

−

6

Heat conductivity

coefficient,

k

, W/(m

∙

◦

C)

237

15

150

40

1,35

Stress tensors and deformation tensors consist of

x

,

y

and

z

normal

components and

x–y

,

y–z

и

z–x

tangent components.

The equations of elastic medium motion are obtained if the force of

internal stresses

∇ ∙

σ

is equated to the product of acceleration and mass

of a solid body volume unit (i.e. its density)

ρ

¨u

. The vector form of the

motion equation is

ρ

∂

2

u

∂t

2

=

∇ ∙

σ.

(5)

Here

ρ

— volume density;

u

— displacement vector.

Equations (4) and (5) form a total system of differential equations

in partial derivatives for stresses and deformations. Boundary conditions

should be added to (4) и (5), but we will not dwell on them.

The connection of deformation with temperature is set using thermodynaics

laws. The equation of thermal conductivity at a small thermal disturbance

(i.e. with

(

T

−

T

0

)

/T

0

1

) can be written as

C

V

∂T

∂t

− ∇

(

k

∇

T

) = ˙

q,

(6)

where

C

V

=

ρC

p

— volumetric heat capacity;

C

p

— specific heat;

k

(

χ

)

—

heat conductivity coefficient;

˙

q

— heat source, namely, heat generation rate

in the unit of volume.

In case of thermoelastic heating, the heat source for an isotropic material

is determined as follows:

˙

q

=

−

EαT

0

(1

−

2

ν

)

∂e

∂t

,

(7)

ISSN 0236-3933. HERALD of the BMSTU. Series Instrument Engineering. 2015. No. 2

31